The Makerspace is the heart of our biomedical engineering lab. Equipped with a FormLabs 3D printer system, Glowforge, ultrasonic cutter, Dremel tools, electronics workstation, and a plethora of other handheld tools, the Makerspace breeds innovation.

We use our FormLabs Form 2 printing system to produce and update prototypes almost instantaneously, create models, develop devices for our research, and even print specific tools needed for bench-top experiments.

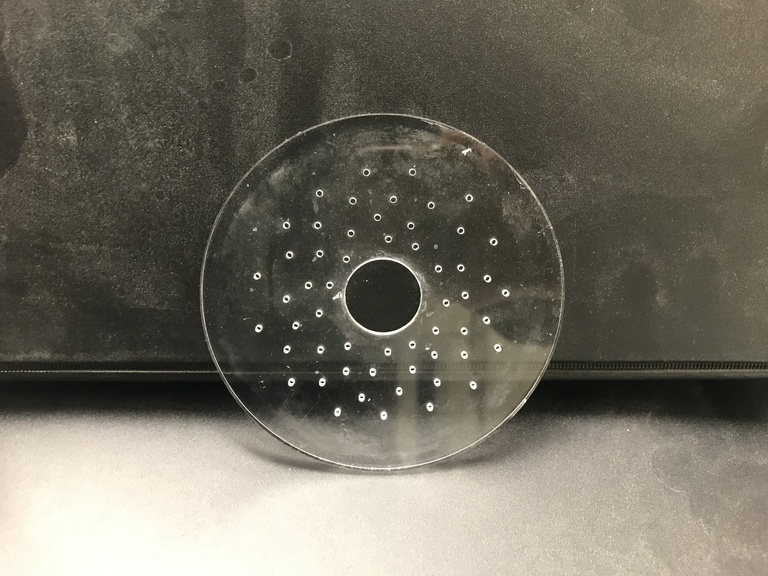

Currently, we have employed our 3D printing system to develop devices for drug delivery systems, create additions to tools used in pre-clinical research, and make models for future experiments.

3D printing has been identified as the future of science and healthcare. From modeling to prototyping to research, 3D printing allows biomedical engineering to become more efficient, economical, and employable.

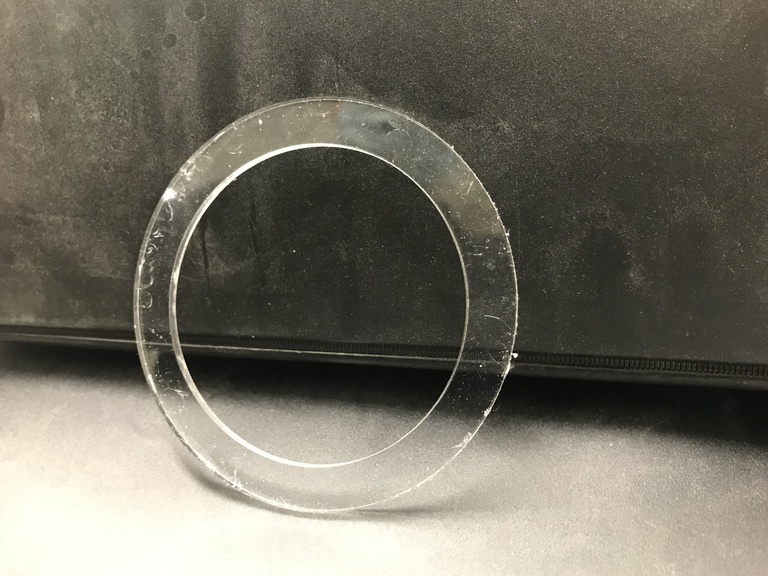

The Glowforge is a 3D laser printer that uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials. In our lab, the Glowforge is used to cut acrylic and wood for our novel experiments.

WE CURRENTLY HAVE BME UNDERGRADUATE RESEARCHERS DEDICATED TO DEVICE DESIGN, DEVELOPMENT, AND PROTOTYPING.